What Are You Looking For?

Truck container door seals play a crucial role in protecting the contents of containers from various external factors such as water,air,and cold.They are widely used in shipping containers,refrigerated containers,and cold storage facilities to ensure that the goods inside remain safe and undamaged during transportation and storage.

Materials:PVC and EPDM

Two of the most commonly used materials for these seals are PVC(Polyvinyl Chloride)and EPDM(Ethylene Propylene Diene Monomer).Both materials offer unique advantages that make them suitable for different applications.

• PVC is known for its durability,resistance to weather,and ability to withstand wear and tear.It is a rigid material that provides a firm seal and is often used in combination with rubber to create a composite seal.PVC seals are ideal for long-term use and can handle harsh environmental conditions.

• EPDM,on the other hand,is a synthetic rubber that is highly flexible and elastic.It is resistant to extreme temperatures,ozone,and UV radiation,making it perfect for outdoor applications.EPDM seals are excellent for creating airtight and watertight seals,ensuring that no moisture or air can enter the container.

Soft and Hard Composite Seals

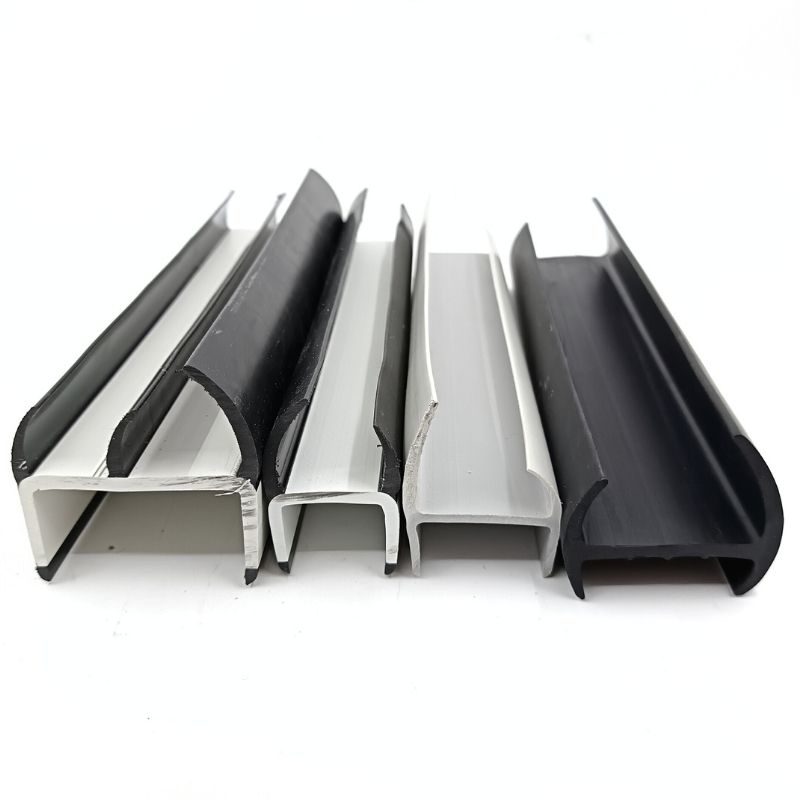

To combine the benefits of both materials,soft and hard composite seals are often used.These seals consist of a soft rubber part that provides flexibility and a hard PVC part that offers rigidity and durability.The soft rubber part ensures a tight seal by conforming to the shape of the door edges,while the hard PVC part provides structural support and resistance to wear.

• Production Process:The production of these composite seals involves co-extrusion,where both materials are extruded together to form a single seal.This process ensures that the two materials are bonded together seamlessly,creating a strong and reliable seal.

• Customization:Composite seals can be customized in terms of size,shape,and hardness to meet specific requirements.They can be made in various shapes such as U-shape,I-shape,and E-shape to fit different types of container doors.

Applications

Truck container door seals made of PVC and EPDM are used in a variety of applications,including:

• Shipping Containers:These seals are essential for protecting goods during long-distance transportation by sea,rail,or road.They prevent water ingress and keep the cargo dry.

• Refrigerated Containers:In cold storage and refrigerated transportation,EPDM seals are particularly important as they maintain the cold temperature inside the container by preventing cold air leakage.

• Cold Storage Facilities:EPDM seals are used in cold rooms and freezers to maintain a consistent temperature and prevent the ingress of warm air,which can cause condensation and spoilage of goods.

Benefits

The use of PVC and EPDM seals offers several benefits:

• Waterproof and Airtight:These seals create a watertight and airtight barrier,preventing water,air,and dust from entering the container.

• Durability:Both PVC and EPDM are highly durable materials that can withstand harsh weather conditions and repeated use.

• Temperature Resistance:EPDM seals can operate in a wide temperature range,from-40°C to+120°C,making them suitable for both hot and cold environments.

• Ease of Installation:Composite seals are easy to install and can be customized to fit different container door configurations.

Truck container door seals made of PVC and EPDM are essential components in the transportation and storage of goods.They provide a reliable and durable solution for preventing leakage and maintaining the integrity of the container's contents.Whether it's protecting against water ingress in shipping containers or maintaining the cold temperature in refrigerated units,these seals play a vital role in ensuring the safety and quality of goods during transportation and storage.