What Are You Looking For?

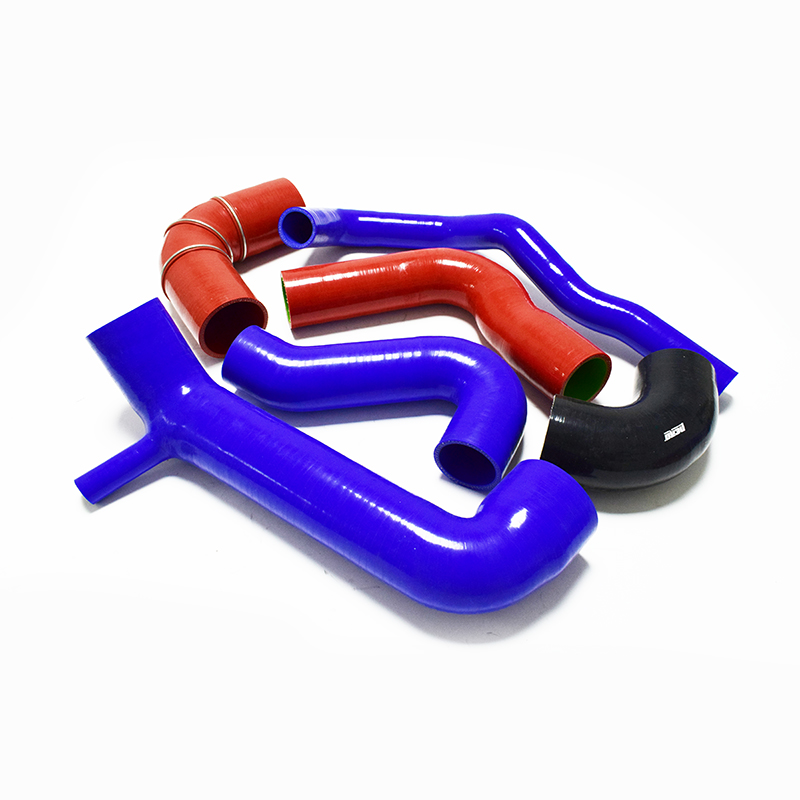

Automotive silicone hoses represent a vital component in modern vehicles, fulfilling critical roles across various systems. Known for their durability, flexibility, and heat resistance, silicone hoses play an indispensable role in ensuring efficient operation and longevity of automotive engines.

Silicone hoses are prominently used in cooling systems, where they channel coolant fluid between the engine, radiator, and heater core. Their ability to withstand high temperatures and pressures makes them ideal for this demanding application. By efficiently transferring coolant, silicone hoses help regulate engine temperature, preventing overheating and ensuring optimal performance.

In addition to cooling systems, silicone hoses are integral to air intake systems. They connect components such as air filters, turbochargers, intercoolers, and intake manifolds, delivering air to the engine. Their smooth inner surface minimizes air resistance, improving airflow efficiency and enhancing engine performance. Silicone's resistance to deformation under suction conditions ensures consistent airflow, crucial for maintaining engine power and efficiency.

Furthermore, automotive silicone hoses are favored in applications where resistance to environmental factors is crucial. They exhibit exceptional resistance to ozone, UV radiation, moisture, and various chemicals, ensuring longevity even in harsh operating conditions. This resilience reduces maintenance requirements and enhances the overall reliability of the vehicle.

Silicone hoses also find use in auxiliary systems such as vacuum lines, windshield washer systems, and EGR (exhaust gas recirculation) systems. Their flexibility and reliability make them suitable for intricate routing in compact engine compartments, optimizing space utilization and installation ease.

Manufacturers and engineers value silicone hoses for their versatility and performance advantages over traditional rubber hoses. Silicone's ability to maintain flexibility across a wide temperature range (-50°C to 200°C or more) ensures reliable operation in both extreme cold and hot environments. This thermal stability minimizes the risk of hose failure due to temperature-induced cracking or hardening, common issues with rubber hoses.

From a manufacturing perspective, silicone hoses are produced using advanced extrusion techniques, allowing for precise customization in terms of size, shape, and reinforcement. Various layers of silicone and fabric or wire reinforcements can be incorporated to meet specific performance requirements, such as high-pressure applications in turbocharged engines.

In conclusion, automotive silicone hoses represent a cornerstone of modern vehicle design, offering durability, flexibility, and high performance across critical systems. Their role in cooling, air intake, and auxiliary applications underscores their importance in maintaining engine efficiency and reliability. As automotive technology continues to advance, silicone hoses will remain integral to enhancing vehicle performance and longevity, meeting the evolving demands of efficiency and environmental sustainability in the automotive industry.

If you need anything, please contact us,Customized different size/color/shape silicone rubber hose, making molds depending on your samples or drawings. FREE SAMPLES can be sent for your evaluation!

Over 20 years Professional Experience in Auto Accessories Field