What Are You Looking For?

EPDM foam sealing strips have become an indispensable component in various industries due to their exceptional performance and wide range of applications.These sealing strips are designed to provide effective sealing solutions,ensuring durability,flexibility,and reliability in numerous scenarios.

Wide Range of Applications

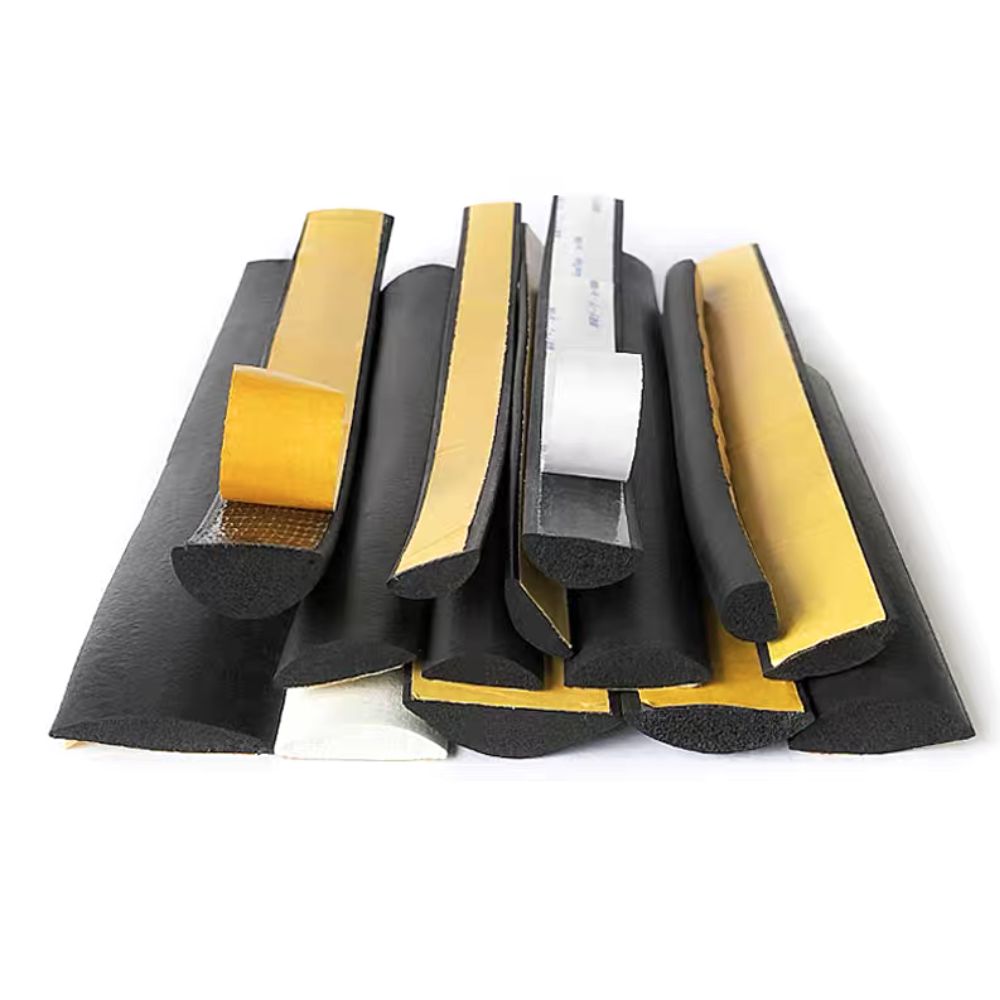

EPDM foam sealing strips are renowned for their versatility.They are extensively used in the automotive and truck industries,where they play a crucial role in sealing doors,windows,and hoods to prevent water ingress and reduce noise.In electrical cabinets,these strips help to seal gaps,protecting sensitive equipment from dust and moisture.Additionally,they are widely employed in mechanical sealing applications to prevent fluid leakage and provide cushioning,ensuring smooth operation and reducing wear and tear.

Customizable Dimensions

One of the key advantages of EPDM foam sealing strips is their ability to be customized to specific dimensions.Whether it is for a small electrical enclosure or a large truck door,these strips can be tailored to fit the exact requirements of the application.This customization ensures a perfect fit,enhancing the effectiveness of the seal and minimizing the risk of leaks or gaps.

Adhesive Options

EPDM foam sealing strips are available with or without adhesive backing,offering flexibility based on the user's needs.The adhesive-backed version provides an easy and efficient installation process,allowing the strips to be securely attached to surfaces without the need for additional fasteners.This feature is particularly beneficial in applications where quick installation and maintenance are required.

Durability and Elasticity

The material properties of EPDM foam sealing strips make them highly durable and elastic.EPDM(Ethylene Propylene Diene Monomer)is known for its excellent resistance to weathering,UV radiation,and ozone,ensuring that the strips maintain their performance even in harsh environmental conditions.The foam structure of the strips provides excellent elasticity,allowing them to conform to irregular surfaces and maintain a tight seal over time.This elasticity also contributes to their wear resistance,making them suitable for applications where frequent movement or vibration is present.

Conclusion

EPDM foam sealing strips are a reliable and versatile solution for a wide range of sealing and cushioning needs.Their customizable dimensions,adhesive options,and durable,elastic properties make them an ideal choice for industries such as automotive,electrical,and mechanical.By providing effective sealing and protection against environmental factors,EPDM foam sealing strips contribute to the longevity and efficiency of various equipment and systems.