What Are You Looking For?

Silicone seal strips are essential components used across various industries for sealing gaps, preventing leaks, and providing insulation. These strips, made from high-quality silicone rubber, offer a unique combination of flexibility, durability, and resistance to extreme conditions. Whether for use in construction, automotive, electronics, or home applications, silicone seal strips are a reliable and cost-effective solution to many sealing challenges. In this article, we will explore what silicone seal strips are, their key benefits, and the diverse applications in which they are used.

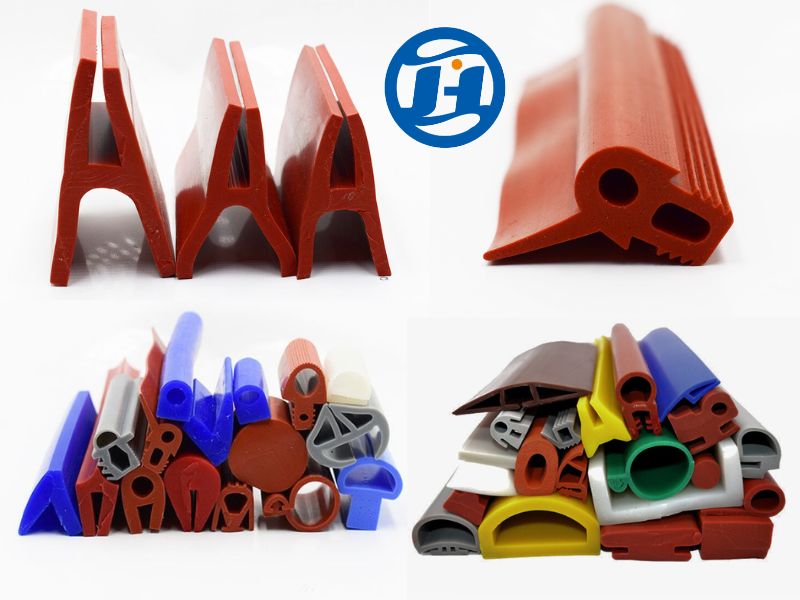

Silicone seal strips are flexible, elastic strips made from silicone rubber, designed to create a tight, secure seal between two surfaces. These strips are often used to fill gaps, prevent the ingress of air, water, dust, and other contaminants, and improve insulation and energy efficiency. Silicone seal strips can be manufactured in a variety of shapes, sizes, and profiles, such as flat, round, or rectangular, to meet the specific sealing needs of different applications.

Excellent Temperature Resistance

Silicone rubber is known for its ability to withstand extreme temperatures. Silicone seal strips can operate in a temperature range from -55°C to +300°C (-67°F to 572°F), making them suitable for use in both high-heat and low-temperature environments. This makes silicone seal strips ideal for sealing applications in industries like automotive, construction, and electronics, where temperature fluctuations are common.

Weatherproof and Waterproof

Silicone seal strips provide excellent protection against water, rain, snow, and humidity. The material is inherently waterproof and can prevent the entry of moisture or other environmental elements, making it ideal for outdoor applications. In addition, silicone’s resistance to UV radiation ensures that the strips won’t degrade or crack under prolonged exposure to sunlight.

Chemical and Corrosion Resistance

Silicone rubber is highly resistant to many chemicals, oils, and solvents. This makes silicone seal strips perfect for sealing in environments where exposure to harsh chemicals or corrosive substances is common. They are also resistant to oxidation and corrosion, ensuring long-lasting durability in demanding environments.

Superior Flexibility and Elasticity

Silicone seal strips are highly flexible and can conform to a wide range of surfaces, providing a tight and secure seal even in uneven or irregularly shaped gaps. Their elasticity allows them to absorb shocks, vibrations, and slight movements without losing their sealing integrity, which is particularly beneficial in automotive and industrial applications.

Noise and Vibration Reduction

Due to their ability to absorb shocks and vibrations, silicone seal strips are often used to reduce noise and vibrations in vehicles, machinery, and building structures. This feature contributes to creating quieter, more comfortable environments, especially in applications where noise reduction is a priority.

Non-Toxic and Safe

Silicone seal strips are non-toxic, hypoallergenic, and safe for use in a variety of applications where human contact is involved, such as in food processing or medical environments. This makes silicone a preferred material for applications requiring high levels of safety and hygiene.

1. Automotive Industry

Silicone seal strips are widely used in the automotive sector for sealing doors, windows, sunroofs, trunks, and other parts of the vehicle. These seals help prevent water, dust, and noise from entering the cabin, improving passenger comfort and the vehicle's overall performance. Silicone’s resistance to temperature extremes and chemicals also ensures the seals remain effective in harsh conditions, such as engine compartments.

2. Construction and Building

In construction, silicone seal strips are commonly used to seal gaps and joints around doors, windows, and roofing systems. The strips provide an airtight and watertight seal, which enhances insulation and energy efficiency in buildings. By preventing drafts and moisture ingress, silicone seal strips help to maintain a comfortable indoor environment and protect building structures from water damage and mold growth.

3. Electronics and Electrical Equipment

Silicone seal strips play an important role in protecting sensitive electronic devices from moisture, dust, and other contaminants. They are often used in smartphones, computers, cameras, and appliances to create a protective barrier, ensuring the longevity and reliability of the devices. Silicone’s ability to withstand extreme temperatures and UV exposure makes it particularly useful in outdoor electronic equipment, such as outdoor security cameras and sensors.

4. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, silicone seal strips are used to seal ducts, vents, and joints to prevent air leakage. This contributes to improving energy efficiency by ensuring that air is properly directed through the system and reducing energy loss. Silicone seal strips are also used in sealing the gaps around air conditioning units and window seals to improve insulation.

5. Food and Beverage Industry

Silicone seal strips are used in food processing, packaging, and storage applications due to their non-toxic nature and resistance to high temperatures. They are commonly found in ovens, refrigerators, and other food equipment to prevent contamination and maintain sanitary conditions. Silicone seal strips are also used to create airtight seals on food containers, preserving freshness and preventing spoilage.

6. Medical Applications

Silicone seal strips are used in medical equipment and devices such as sterile packaging, diagnostic instruments, and pharmaceutical containers. Their non-toxic, hypoallergenic properties make them ideal for applications where patient safety is critical. Silicone's resistance to sterilization methods like autoclaving further enhances its suitability for use in medical environments.

7. Marine and Aerospace

In the marine and aerospace industries, silicone seal strips are used for sealing windows, doors, hatches, and other critical components. These seals help protect against water, salt, and environmental contaminants, ensuring the integrity of equipment exposed to harsh marine or aerospace conditions. Silicone’s resilience to extreme temperatures and weather conditions ensures long-lasting performance in these challenging environments.

Silicone seal strips are highly versatile, providing an effective solution for sealing, insulating, and protecting across a wide range of industries and applications. Their resistance to extreme temperatures, chemicals, moisture, and UV radiation, combined with their flexibility and durability, make them an ideal choice for sealing solutions. Whether you're in the automotive, construction, electronics, or food processing industries, silicone seal strips offer unmatched reliability and performance. By investing in high-quality silicone seal strips, you can ensure long-term protection, improved efficiency, and enhanced comfort in your products and systems.

If you need anything, please contact us,Customized different size/color/shape silicone rubber hose, making molds depending on your samples or drawings. FREE SAMPLES can be sent for your evaluation!

Over 20 years Professional Experience in Auto Accessories Field