What Are You Looking For?

Understanding H and J Type Seals

Truck container door seals come in various shapes and sizes,with the H and J types being two of the most commonly used profiles.Each type offers unique advantages and is tailored to meet specific requirements.

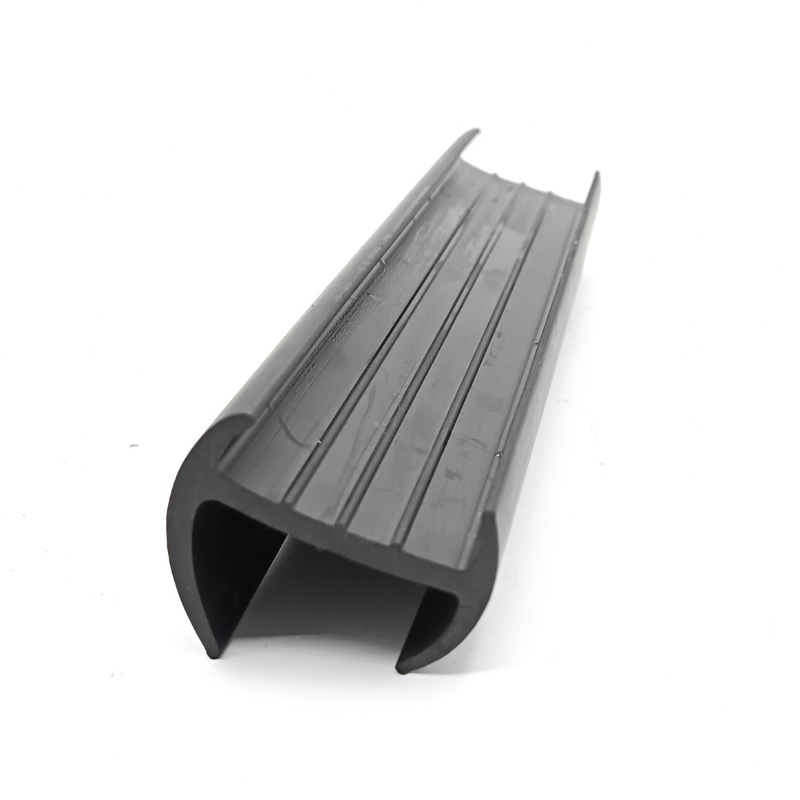

H Type Seals

The H type seal is characterized by its symmetrical shape,resembling the letter"H."This design allows for even contact on both sides of the door frame,ensuring a consistent seal.It is particularly effective in preventing the ingress of dust,water,and air,making it ideal for applications where maintaining a clean and controlled environment inside the container is crucial.The H type seal is often preferred for its robustness and ability to withstand varying degrees of pressure and wear.

J Type Seals

The J type seal,on the other hand,has an asymmetrical profile that resembles the letter"J."This shape provides a snug fit against the door edge,creating a tight seal that is highly effective in preventing leaks and drafts.The J type seal is known for its flexibility and adaptability,making it suitable for a wide range of door sizes and configurations.Its design also allows for easy installation,reducing the time and effort required during the sealing process.

Material Options:PVC,EPDM,and TPE

One of the key factors that determine the performance and longevity of a truck container door seal is the material used in its construction.Manufacturers offer a variety of materials to cater to different needs and preferences.The three most popular choices are PVC,EPDM,and TPE,each with its own set of characteristics and benefits.

PVC(Polyvinyl Chloride)

PVC is a widely used material known for its affordability,durability,and resistance to sunlight,chemicals,and fire.It offers excellent weathering properties,making it suitable for outdoor applications.PVC seals are also easy to clean and maintain,which is essential for ensuring their continued effectiveness.However,PVC may not be as flexible as some other materials,especially at lower temperatures,which could be a consideration in certain climates.

EPDM(Ethylene Propylene Diene Monomer)

EPDM is a synthetic rubber that is highly regarded for its superior resistance to weathering,UV rays,and extreme temperatures.It maintains its flexibility and elasticity over a wide temperature range,from-40°C to+120°C,making it an excellent choice for applications in diverse climates.EPDM seals are also known for their excellent aging resistance,ozone resistance,and chemical stability,ensuring long-term performance and reliability.Additionally,EPDM is resistant to a variety of refrigerants,making it suitable for use in refrigerated containers.

TPE(Thermoplastic Elastomer)

TPE is a versatile material that combines the properties of rubber with the processing advantages of thermoplastics.It offers a balance of flexibility,durability,and resistance to various environmental factors.TPE seals are easy to install and can be customized to meet specific hardness requirements,making them suitable for a wide range of applications.They also exhibit good resistance to oil,chemicals,and abrasion,ensuring long-lasting performance.

Customization for Optimal Fit and Functionality

One of the most significant advantages of modern truck container door seals is the ability to customize them to meet specific requirements.This customization extends to various aspects,including shape,size,material,and hardness,ensuring that the seal is perfectly suited to the application.

Shape Customization

Whether you need an H type,J type,or any other custom shape,manufacturers can tailor the seal profile to match the exact dimensions and contours of your container door.This ensures a precise fit,maximizing the seal's effectiveness in preventing leaks and maintaining insulation.

Size Customization

Container doors come in various sizes,and so do the seals.Manufacturers can produce seals in lengths ranging from a few meters to several hundred meters,depending on the customer's needs.This flexibility allows businesses to order the exact amount of sealing material required,minimizing waste and optimizing costs.

Material and Hardness Customization

Customers can choose from PVC,EPDM,TPE,or a combination of these materials,depending on the desired properties.Additionally,the hardness of the seal can be adjusted within a specified range(e.g.,30-90 Shore A)to achieve the desired balance between flexibility and durability.This level of customization ensures that the seal performs optimally in its intended environment.

Key Features and Benefits

Insulation

Effective insulation is crucial for maintaining the temperature inside the container,especially for refrigerated trucks and containers.The seals are designed to minimize heat transfer,ensuring that the contents remain at the desired temperature and reducing the load on the cooling system.

Waterproofing

Preventing water ingress is essential for protecting the goods from moisture damage.The seals create a watertight barrier,keeping out rainwater,humidity,and other sources of moisture.This is particularly important for sensitive cargo such as electronics,perishable goods,and pharmaceuticals.

Fire Resistance

In the event of a fire,fire-resistant seals can help contain the flames and prevent them from spreading to the container's contents.This is a critical safety feature,especially for high-value or hazardous cargo.

Corrosion Resistance

Exposure to harsh environmental conditions can lead to corrosion,which can compromise the integrity of the container and its contents.Corrosion-resistant seals help protect against rust and other forms of degradation,ensuring the longevity of the container and its components.

About JINHU

With over 20 years of professional experience, JINHU is a trusted manufacturer of high-quality rubber and silicone products, including mudflaps, sealing strips, and more. Visit our website to explore our full range of products: