What Are You Looking For?

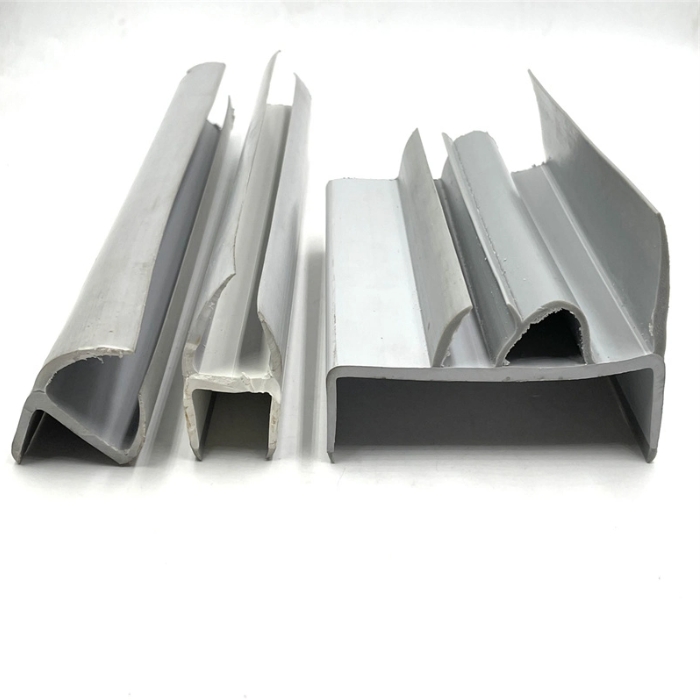

In the realm of industrial sealing solutions, the H-type seal stands out due to its robust design and versatile applications. What makes this seal even more impressive is the dual-component extrusion technology that combines both soft and hard materials, enhancing its performance in a variety of demanding environments.

The Design Innovation: Soft and Hard Co-Extrusion

The H-type seal leverages a sophisticated co-extrusion process, blending two distinct materials—soft and hard elastomers—into a single, cohesive unit. This innovation ensures that the seal not only meets but exceeds performance expectations across a range of industrial applications.

Key Advantages of the H-Type Seal

Enhanced Durability: The hard component of the seal provides structural strength and resistance to physical wear and tear. Meanwhile, the soft component ensures excellent flexibility and adaptability, allowing the seal to conform to irregularities and withstand dynamic movements without losing effectiveness.

Superior Sealing Performance: The combination of soft and hard materials offers a superior sealing capability, effectively preventing leaks and contamination. This dual-material approach ensures a tight seal even under varying pressures and temperatures, making it ideal for high-demand environments.

Improved Noise and Vibration Reduction: The soft elastomer component helps in damping vibrations and reducing noise, contributing to a quieter and smoother operation. This is particularly beneficial in applications where noise reduction is critical, such as in automotive or machinery settings.

Versatile Applications: The H-type seal is designed to perform in a wide range of industries, including automotive, aerospace, manufacturing, and construction. Its ability to handle diverse conditions—from extreme temperatures to high pressures—makes it a go-to solution for many industrial challenges.

Cost-Effectiveness: By integrating both soft and hard materials, the H-type seal often results in longer service life and reduced maintenance costs. This efficiency translates to significant savings over time, making it a cost-effective choice for many businesses.

Applications in Industry

From automotive doors to machinery housings, the H-type seal excels in applications that require reliable, long-lasting sealing solutions. Its ability to maintain performance under varying conditions and its resilience to environmental factors make it a preferred choice for industries that demand precision and durability.

Conclusion

The H-type industrial seal with its soft and hard co-extrusion technology represents a significant advancement in sealing solutions. By combining the best properties of both materials, it offers unparalleled durability, sealing performance, and versatility. For industries seeking a reliable and cost-effective sealing solution, the H-type seal stands as a testament to engineering innovation and practical application.

As industries continue to evolve and face new challenges, the H-type seal's ability to adapt and perform remains a cornerstone of industrial sealing technology. Whether you’re dealing with high pressure, extreme temperatures, or complex applications, the H-type seal is designed to meet and exceed your expectations.

If you need anything, please contact us,Customized different size/color/shape silicone rubber hose, making molds depending on your samples or drawings. FREE SAMPLES can be sent for your evaluation!

Over 20 years Professional Experience in Auto Accessories Field