What Are You Looking For?

In the world of global trade and logistics, the safe and secure transport of goods is a top priority. Among the various components of a shipping container, the container door seal plays a critical role in ensuring cargo remains protected during transit. This unassuming yet essential component prevents the intrusion of external elements, such as water, dust, and pests, while maintaining the integrity of the container's contents. In this article, we’ll explore the importance, types, and maintenance of container door seals, as well as how they contribute to the safety and efficiency of shipping operations.

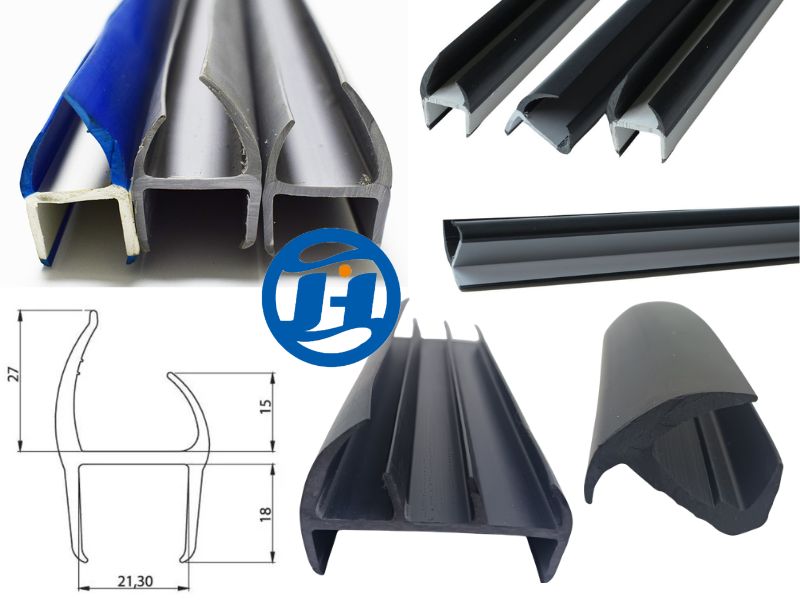

A container door seal is a rubber or synthetic gasket that is mounted along the edges of a shipping container’s door. It acts as a barrier between the container door and the doorframe, effectively preventing air, moisture, and foreign materials from entering the container. This simple yet vital part of the container ensures that goods remain safe, secure, and free from contamination during transit, especially for long distances or harsh environmental conditions.

Weatherproofing: One of the primary functions of a door seal is to protect the cargo from the elements. Shipping containers often travel through varied climates, from torrential rains to high humidity or extreme cold. The door seal prevents rainwater, snow, dust, and other debris from getting inside the container, helping to preserve the quality of sensitive goods such as electronics, textiles, and perishables.

Security: The integrity of a shipping container is not only about weatherproofing but also about ensuring the cargo remains secure from unauthorized access. The seal contributes to the overall security of the container, making it more difficult for thieves or intruders to tamper with the contents. In some cases, containers are equipped with tamper-evident seals that show signs of any unauthorized opening or interference.

Pest Control: Container door seals also serve as a barrier against pests, including insects and rodents, which can potentially damage or contaminate the cargo. This is particularly important for the agricultural industry, where the risk of pests infesting shipments of food or plant products is a major concern.

Temperature Regulation: For goods that require temperature control, such as pharmaceuticals or perishable food items, an effective door seal helps maintain the internal climate of the container. By minimizing air exchange between the container's interior and the outside environment, the seal contributes to temperature stability and prevents spoilage due to fluctuating external temperatures.

There are several types of container door seals, each suited for different applications and environmental conditions. The most common types include:

Single Flap Seals: These are the most basic type of seals and consist of a single layer of rubber or synthetic material that creates a simple barrier against the elements. They are commonly used in standard shipping containers and are effective for general-purpose cargo.

Double Flap Seals: These seals feature two overlapping flaps that offer additional protection. The double flap design provides a better seal against water and dust infiltration, making it ideal for containers that will be exposed to harsh weather or for long-distance voyages.

Inflatable Seals: These seals are equipped with an internal air bladder that inflates to create a tight, secure seal when the container doors are closed. Inflatable seals are particularly useful in containers carrying high-value or sensitive goods, as they provide a higher level of protection against environmental factors.

Magnetic Seals: Magnetic door seals use magnets embedded in the rubber to create a more airtight and tamper-resistant closure. These seals are commonly found on refrigerated containers (reefers) and are designed to prevent any temperature fluctuations that might affect perishable goods.

Heavy-Duty Seals: For containers transporting bulky or heavy goods, a heavy-duty seal may be used. These seals are reinforced with additional layers of rubber or other materials to withstand the pressures of loading, unloading, and long transit times.

Proper maintenance of container door seals is essential to ensuring their continued performance and effectiveness. Over time, seals can become damaged, brittle, or deformed due to exposure to the elements or frequent use. To prolong their lifespan, it’s important to regularly inspect the seals for signs of wear and tear, including cracks, punctures, or loss of elasticity. If any damage is identified, the seal should be replaced immediately to prevent any loss of functionality.

Here are some key maintenance tips for container door seals:

Clean the Seals Regularly: Dirt, salt, and other debris can accumulate on the seals over time, potentially compromising their effectiveness. Cleaning the seals with a mild detergent and water helps to remove any contaminants that might cause wear.

Lubricate the Seals: Applying a rubber-friendly lubricant to the seals can help maintain their flexibility and prevent cracking. However, it's important to use a lubricant that is compatible with the material of the seal to avoid degradation.

Check for Leaks: After loading or unloading a container, inspect the door seals to ensure there are no visible gaps or leaks. For containers that transport sensitive or high-value cargo, it's advisable to conduct periodic leak tests to ensure the seals remain intact.

Replace Damaged Seals: If a seal is damaged or showing signs of wear, it should be replaced immediately to prevent any potential damage to the cargo. Regular inspections are essential to catching damage early.

Container door seals are often overlooked, but they play a critical role in ensuring that cargo arrives at its destination in the same condition it was shipped. By providing weatherproofing, pest control, and security, door seals protect the integrity of goods, improve shipping efficiency, and reduce the likelihood of costly damage or losses. For businesses engaged in international trade, maintaining the quality and functionality of these seals is essential for safeguarding their goods and ensuring customer satisfaction.

Whether you're shipping industrial equipment, electronics, food products, or agricultural goods, the quality of the container door seal directly impacts the success of your shipment. By understanding the various types of seals and their maintenance needs, businesses can enhance the safety and security of their cargo, ensuring smooth and successful international trade operations.

If you need anything, please contact us,Customized different size/color/shape silicone rubber hose, making molds depending on your samples or drawings. FREE SAMPLES can be sent for your evaluation!

Over 20 years Professional Experience in Auto Accessories Field